Spindles play a crucial role in the modern manufacturing industry in which accuracy, reliability speed, and precision are essential. When it comes to carving aerospace-grade metals or fine-tuning high-tolerance components to fit medical devices, the machining spindle is the unnoticed force behind accuracy, speed, and the utmost consistency.

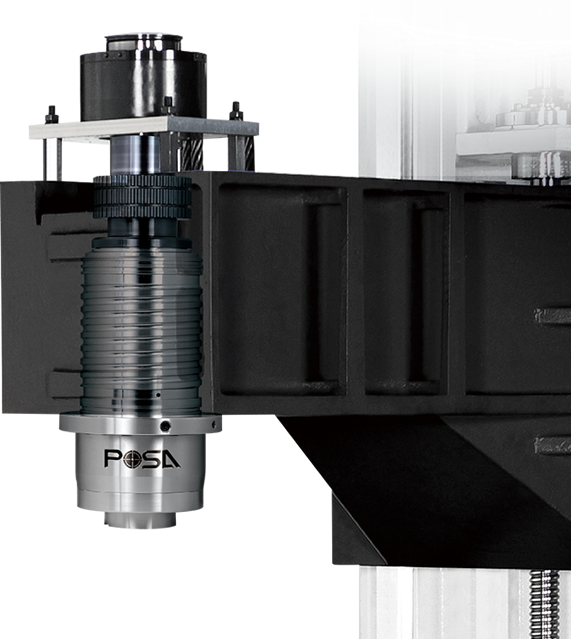

In the forefront of this niche industry are top spindle producers like POSA Machinery which are revolutionizing what the performance and durability of their products look like in industrial machining environments.

Image credit: posa-spindle.com

The Spindle is the core of the Machine.

Every CNC machine is only as effective as its spindle. Imagine that the spindle is the center of a CNC lathe or machining center. It is the engine that drives the cutting tool at high precision, stability, and torque. A badly designed or incorrectly aligned spindle isn’t only the result of defective parts, it could also damage the machine, decrease time-to-market, and shut off the entire production cycle.

This is where precision technology spindles can make all the differences. Contrary to conventional parts that are mass-produced and assembled in a hurry Precision spindles are carefully developed, tested, and calibrated to work in extreme conditions and on the highest demand.

POSA More than a Spindle Manufacture

POSA Machine has been a leading company in spindle production for years. While many spindle manufacturers claim to be high-precision however, they lack the expertise and technical expertise POSA has gained over those years. Known for their rigorous internal testing procedures and commitment to international quality standards, POSA does more than just manufacture spindles, they create solutions designed to meet the diverse needs of today’s industries.

From high-speed micro-machining to the most powerful material removal machines Spindles from POSA can be found in everything from grinding machines for tools to vertical and horizontal CNC centers. Every spindle is backed by an extensive R&D process that focuses not only on function but also on long-term reliability and vibration control, as well as thermal stability.

The Evolution of the CNC Lathe Spindle

The CNC lathe spindle has seen remarkable innovation in recent years. Spindles today are more than just a rotating shaft. They include sensors, cooling systems, as well as a an intelligent balance mechanism. POSA CNC spindles offer a great example. They combine speedy capabilities and high torque with precision and rigidity, making it possible for machinists to work with both delicate metals and soft materials. Incorporating advanced ceramic bearings and premium steel construction, these spindles minimize thermal expansion while maintaining the tight tolerances during long runs. This type of reliability leads to improved quality of the part with reduced downtime as well as better tolerances.

Customized Machining Spindles that Meet the requirements of the real-world

It’s difficult to find a machining machine that fits all, especially in the fields of automotive, aerospace and die & mould manufacturing. POSA recognizes that every application is unique and has its own set of requirements, be it for spindle speed, load capacity, or environmental resistance. That’s why POSA offers custom spindle designs that are based on the needs of each client. No matter if you’re creating a spindle to be used in vertical milling or integrating spindles with high-frequency into a compact device, POSA offers the flexibility and technical assistance that modern manufacturers require.

More than machines A commitment to handcraftsmanship

The philosophy behind POSA’s spindles is what distinguishes it from the other spindles. The company is a believer in the fusion of craft and innovation. Their design engineers work closely with their customers as they listen to their needs and continue to improve their offerings to stay ahead of market trends and demands. In a world where machine uptime as well as repeatability are crucial to a production line’s success, choosing the right spindle partners is critical.

Final Thoughts

The future of manufacturing is not solely about more efficient machines. It is also about more intelligent and more reliable components. POSA Machine is a great example of what spindle makers can accomplish when they combine their technical expertise with a customer-first mentality. Pick the perfect spindle to meet your needs, regardless of whether you’re in search of a high-performance CNC spindle, or a heavy high-performance machining spindle.